Closure processing equipment for pharma industry

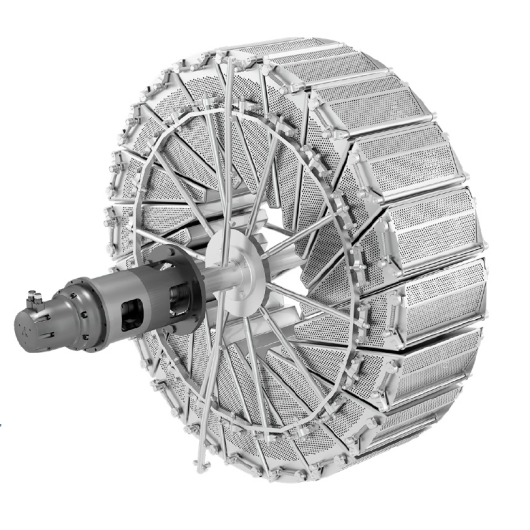

Sterile continuity is the vision. The SPE Series is ideal for treating closures for containers normally used in the pharmaceutical industry, where continuous sterility has to be maintained between different phases. The pharma grade closure processing system fully integrates all the phases of the treatment in an all in one solution:

- Pre-treatment handling

- Washing, rinsing & siliconizing

- Sterilization, drying and cooling

- Sterile delivery

Compatible with different loading/unloading systems, the unit can also be interfaced with vaporized hydrogen peroxide isolator.

Flexibility and versatility characterize the series devices, available in five models with five different chamber capacities – with a chamber volume ranging from 40 to 240 litres (1.4 to 20 cu ft). The high-quality AISI 316 L chamber with a round cross-section and two torispherical heads ensures an even distribution of load in separate baskets for optimized final results. In addition, Steelco produces a “Closure washer” version (SPE-W series) that only provides washing, rinsing, siliconizing, drying, and cooling phases.

The SPE Series is designed, manufactured, validated, and documented according to the latest global practices and standards to facilitate customers’ compliance with current Good Manufacturing Practices (cGMPs).

Taking care of your stoppers from manufacture to point of use

Designed for the complete treatment of closure devices for pharmaceutical products such as:

- Rubber and plastic stoppers

- Plungers

- Tip caps

- Aluminum caps and seals

- Other similar components